Cellulose Derivative Market: Enabling Bio-Innovation in 3D Bioprinting and Sustainable Pharmaceuticals, FMI

The cellulose derivative market is driving innovations in 3D bioprinting, sustainable pharmaceuticals, and eco-friendly cosmetics for a greener future.

NEWARK, DE, UNITED STATES, May 16, 2025 /EINPresswire.com/ -- The cellulose derivative market, long known for its applications in food stabilizers, thickeners, and pharmaceutical excipients, is currently undergoing a transformation, though one that often flies under the radar of mainstream market analysis. While conventional uses such as film coatings in tablets and viscosity control in construction materials continue to dominate volumes, a lesser-known but rapidly expanding frontier is emerging in 3D bioprinting, tissue engineering, and green drug delivery systems.

The growing interest in search queries such as hydroxypropyl methylcellulose in bioprinting, cellulose ether for bio-inks, and cellulose-based drug release matrices underscores this shift. The cellulose derivative market is not just evolving in size but in strategic importance, particularly as biotechnology, sustainable healthcare, and environmentally responsible materials come to the forefront of industrial innovation.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-2470

𝐁𝐢𝐨𝐩𝐫𝐢𝐧𝐭𝐢𝐧𝐠 𝐚𝐧𝐝 𝐑𝐞𝐠𝐞𝐧𝐞𝐫𝐚𝐭𝐢𝐯𝐞 𝐌𝐞𝐝𝐢𝐜𝐢𝐧𝐞: 𝐀 𝐍𝐞𝐰 𝐑𝐨𝐥𝐞 𝐟𝐨𝐫 𝐂𝐞𝐥𝐥𝐮𝐥𝐨𝐬𝐞-𝐁𝐚𝐬𝐞𝐝 𝐁𝐢𝐨-𝐈𝐧𝐤𝐬

One of the most exciting, yet rarely discussed, developments in the cellulose derivative market is its use in 3D bioprinting applications. Here, derivatives such as hydroxyethyl cellulose (HEC), carboxymethyl cellulose (CMC), and methylcellulose (MC) are finding novel applications as rheology modifiers and scaffolding agents in bio-ink formulations. Their biocompatibility, tunable viscosity, and water solubility make them ideal candidates for printing soft tissues and hydrogels.

In 2023, a research consortium led by the University of Gothenburg successfully developed a cellulose-based bio-ink that supported the printing of vascular-like structures. The project utilized a blend of CMC and alginate, showing how plant-derived polymers can support cell adhesion and viability while maintaining structural integrity during and after printing. This application positions cellulose derivatives as key enablers in regenerative medicine, where synthetic polymers often struggle to meet biocompatibility standards.

Bioprinting firms in North America and Europe are now actively investing in cellulose-derived bio-inks, leveraging their eco-friendly profile and clinical safety record. As 3D bioprinting moves toward clinical and pharmaceutical production stages, the demand for GRAS-certified, renewable polymers like cellulose derivatives is expected to surge.

𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐥𝐞 𝐏𝐡𝐚𝐫𝐦𝐚𝐜𝐞𝐮𝐭𝐢𝐜𝐚𝐥 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬: 𝐂𝐨𝐧𝐭𝐫𝐨𝐥𝐥𝐢𝐧𝐠 𝐃𝐫𝐮𝐠 𝐑𝐞𝐥𝐞𝐚𝐬𝐞 𝐰𝐢𝐭𝐡 𝐂𝐞𝐥𝐥𝐮𝐥𝐨𝐬𝐞 𝐏𝐨𝐥𝐲𝐦𝐞𝐫𝐬

Another high-value, under-discussed avenue of growth in the cellulose derivative market is in sustainable drug formulation and controlled release systems. While hydroxypropyl methylcellulose (HPMC) and ethyl cellulose (EC) are already well-known in pharma excipients, the current innovation lies in using these derivatives for zero-waste encapsulation, biodegradable delivery systems, and slow-release therapeutics.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/cellulose-derivative-market

A 2024 study published in Advanced Drug Delivery Reviews explored the efficacy of cellulose acetate phthalate in delivering pH-sensitive anti-inflammatory drugs. The material was shown to improve bioavailability while preventing drug degradation in the upper GI tract. This shows how cellulose derivatives are not just inert carriers, but functional materials actively enhancing therapeutic performance.

Moreover, as the pharmaceutical industry faces pressure to reduce its environmental impact, cellulose derivatives—derived from renewable plant biomass—are being reconsidered as primary components in green pill coatings, transdermal patches, and even edible packaging films. This trend is particularly evident in India and the EU, where new sustainability mandates are pushing formulators to seek biodegradable excipients over synthetic polymers.

𝐂𝐨𝐬𝐦𝐞𝐜𝐞𝐮𝐭𝐢𝐜𝐚𝐥𝐬 𝐚𝐧𝐝 𝐒𝐤𝐢𝐧𝐜𝐚𝐫𝐞: 𝐑𝐞𝐝𝐞𝐟𝐢𝐧𝐢𝐧𝐠 𝐍𝐚𝐭𝐮𝐫𝐚𝐥 𝐅𝐨𝐫𝐦𝐮𝐥𝐚𝐭𝐢𝐨𝐧 𝐒𝐭𝐚𝐧𝐝𝐚𝐫𝐝𝐬

A rising demand for “clean-label,” plant-based skincare products is reshaping formulation strategies in the personal care industry. Cellulose derivatives such as hydroxyethyl cellulose and microcrystalline cellulose are gaining traction as alternatives to silicones and synthetic thickeners. These ingredients not only provide texture and stability but also improve moisture retention and reduce irritation—qualities that align with the booming demand for sensitive-skin products and vegan formulations.

In 2022, a Japanese cosmetic conglomerate introduced a skin serum utilizing methylcellulose microfibers to create a breathable skin barrier. The product received strong consumer interest, particularly in Southeast Asia, where consumers are increasingly scrutinizing ingredient sources and sustainability. As clean beauty trends continue to surge, the demand for cellulose-derived functional materials in skincare is expected to become a key growth lever in the market.

𝐑𝐞𝐠𝐢𝐨𝐧𝐚𝐥 𝐓𝐫𝐞𝐧𝐝𝐬: 𝐁𝐢𝐨𝐞𝐜𝐨𝐧𝐨𝐦𝐲 𝐏𝐨𝐥𝐢𝐜𝐢𝐞𝐬 𝐅𝐮𝐞𝐥 𝐌𝐚𝐫𝐤𝐞𝐭 𝐄𝐱𝐩𝐚𝐧𝐬𝐢𝐨𝐧

Regionally, the cellulose derivative market is seeing accelerated expansion in economies that have embraced the bioeconomy and circular material policy frameworks. The European Union, through programs such as Horizon Europe and the Bio-Based Industries Joint Undertaking (BBI-JU), is funding the development of cellulose-based bioplastics and pharmaceutical-grade materials. Scandinavian nations are leading in converting wood pulp into high-purity cellulose ethers, creating a sustainable alternative to petroleum-based polymers.

China, on the other hand, is investing in high-capacity production of cellulose ethers to serve its rapidly expanding domestic pharmaceutical and construction industries. Companies in Shandong and Jiangsu provinces are refining production processes to meet USP and EP standards, eyeing exports to North America and Europe. Meanwhile, in the U.S., the Inflation Reduction Act has indirectly boosted interest in renewable feedstocks, including wood-derived cellulose for industrial biopolymers and packaging.

𝐏𝐨𝐥𝐲𝐦𝐞𝐫𝐬 & 𝐏𝐥𝐚𝐬𝐭𝐢𝐜𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/polymers-and-plastics

𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐮𝐭𝐥𝐨𝐨𝐤: 𝐒𝐩𝐞𝐜𝐢𝐚𝐥𝐢𝐳𝐚𝐭𝐢𝐨𝐧 𝐚𝐧𝐝 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲 𝐃𝐫𝐢𝐯𝐞 𝐅𝐮𝐭𝐮𝐫𝐞 𝐆𝐫𝐨𝐰𝐭𝐡

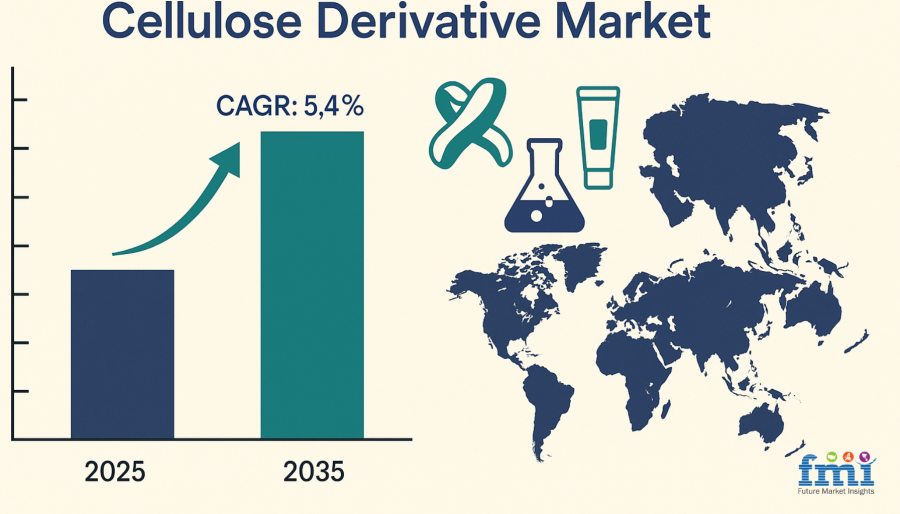

The cellulose derivative market is projected to expand from USD 6,776.6 million in 2025 to USD 11,466.1 million by 2035, reflecting a compound annual growth rate (CAGR) of 5.4% over the forecast period. However, the real story lies not in overall volume but in product diversification and specialized applications. The fastest-growing subsegments—bioprinting, biomedical delivery systems, and eco-formulated cosmetics—represent the highest margins and most strategic innovations in the sector.

Manufacturers are increasingly focusing on high-purity, low-residue cellulose grades suitable for regulated markets. Innovations in enzymatic hydrolysis and green solvent processing are enabling more environmentally sound production methods, which further enhance the market’s appeal to ESG-conscious investors and end users.

𝐂𝐞𝐥𝐥𝐮𝐥𝐨𝐬𝐞 𝐃𝐞𝐫𝐢𝐯𝐚𝐭𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐛𝐲 𝐂𝐚𝐭𝐞𝐠𝐨𝐫𝐲

By Derivative Type:

- Methyl

- Carboxymethyl

- Hydroxyethyl

- Ethyl

- Other Types

By Derivative Grades:

- Food Grade

- Pharmaceutical Grade

- Industrial Grade

By End Use:

- Food Industry

- Pharmaceutical Industry

- Personal Care

- Construction

- Paint Industry

- Others

By Region:

- North America

- Latin America

- Europe

- Asia Pacific

- The Middle East and Africa

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Flue Gas Desulfurization System Market: https://www.futuremarketinsights.com/reports/flue-gas-desulfurization-system-market

Formaldehyde-Free Resin Market: https://www.futuremarketinsights.com/reports/formaldehyde-free-resin-market

Nylon-6 Market: https://www.futuremarketinsights.com/reports/polyamide-6-market

Industrial Insulation Market: https://www.futuremarketinsights.com/reports/industrial-insulation-market

Industrial Gases Market: https://www.futuremarketinsights.com/reports/industrial-gases-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release