How Additive Manufacturing is Reshaping the Aviation Titanium Alloy Market Supply Chain, FMI Study

Additive manufacturing is transforming the aviation titanium alloy market by reducing waste, shortening lead times & enabling decentralized aerospace production

NEWARK, DE, UNITED STATES, May 16, 2025 /EINPresswire.com/ -- The aviation industry has long relied on aviation titanium alloy for its exceptional performance characteristics—high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. As aircraft design continues to evolve with increased demands for fuel efficiency and durability, aviation titanium alloy has become a staple material in airframes, engines, and other critical components. However, the conventional supply chain for aerospace-grade titanium alloys has often been marked by inefficiencies, high material wastage, and long production cycles. A less frequently examined but transformative shift in this space is the rise of additive manufacturing (AM), also known as 3D printing, and its disruptive impact on the aviation titanium alloy supply chain within aerospace manufacturing.

𝐓𝐡𝐞 𝐑𝐨𝐥𝐞 𝐨𝐟 𝐀𝐯𝐢𝐚𝐭𝐢𝐨𝐧 𝐓𝐢𝐭𝐚𝐧𝐢𝐮𝐦 𝐀𝐥𝐥𝐨𝐲 𝐢𝐧 𝐀𝐯𝐢𝐚𝐭𝐢𝐨𝐧

Aviation titanium alloy, particularly grades like Ti-6Al-4V, plays a pivotal role in the structural and engine components of both commercial and military aircraft. These alloys are favored due to their ability to maintain structural integrity under high stress and heat, making them ideal for components like turbine blades, compressor parts, and load-bearing structures in airframes. Boeing’s 787 Dreamliner, for instance, incorporates approximately 15% titanium by weight, largely due to its composite-intensive structure. Similarly, military jets such as the F-22 Raptor rely heavily on aviation titanium alloy for stealth and speed advantages.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-17408

𝐓𝐫𝐚𝐝𝐢𝐭𝐢𝐨𝐧𝐚𝐥 𝐀𝐯𝐢𝐚𝐭𝐢𝐨𝐧 𝐓𝐢𝐭𝐚𝐧𝐢𝐮𝐦 𝐀𝐥𝐥𝐨𝐲 𝐒𝐮𝐩𝐩𝐥𝐲 𝐂𝐡𝐚𝐢𝐧𝐬: 𝐀 𝐁𝐨𝐭𝐭𝐥𝐞𝐧𝐞𝐜𝐤 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬

Historically, the aerospace-grade aviation titanium alloy supply chain has involved a complex network of mining, processing, forging, machining, and quality assurance—all of which contribute to long lead times and elevated production costs. Machining titanium components from forged billets typically results in high material wastage, sometimes exceeding 80%, which adds significant cost burdens. Additionally, sourcing high-purity sponge titanium and converting it into usable forms involves multi-step processes that often span across continents and involve substantial logistical overhead. Delays in these stages can disrupt aircraft production schedules, making supply chain optimization a key priority for aerospace original equipment manufacturers (OEMs).

𝐀𝐝𝐝𝐢𝐭𝐢𝐯𝐞 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠 𝐚𝐬 𝐚 𝐆𝐚𝐦𝐞 𝐂𝐡𝐚𝐧𝐠𝐞𝐫 𝐟𝐨𝐫 𝐀𝐯𝐢𝐚𝐭𝐢𝐨𝐧 𝐓𝐢𝐭𝐚𝐧𝐢𝐮𝐦 𝐀𝐥𝐥𝐨𝐲

Additive manufacturing offers a radically different approach to producing aviation titanium alloy parts by building them layer by layer from titanium powder, thus eliminating the need for traditional subtractive processes. This technology drastically reduces material waste—sometimes by as much as 90%—and shortens production timelines. For instance, titanium brackets that once took months to manufacture via forging and machining can now be printed in a matter of days. This agility is particularly valuable in low-volume, high-complexity aerospace production, where custom parts are often needed on demand.

The use of 3D printing also facilitates the integration of more complex geometries that are either too difficult or impossible to achieve with traditional methods. Powder bed fusion and direct metal laser sintering (DMLS) are among the most widely used techniques in aerospace applications. These methods have enabled innovations such as hollow structures that maintain strength while reducing weight, an essential factor in improving fuel efficiency and range in modern aircraft.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/aviation-titanium-alloy-market

𝐂𝐚𝐬𝐞 𝐒𝐭𝐮𝐝𝐢𝐞𝐬 𝐚𝐧𝐝 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐄𝐱𝐚𝐦𝐩𝐥𝐞𝐬 𝐢𝐧 𝐀𝐯𝐢𝐚𝐭𝐢𝐨𝐧 𝐓𝐢𝐭𝐚𝐧𝐢𝐮𝐦 𝐀𝐥𝐥𝐨𝐲 𝐀𝐝𝐝𝐢𝐭𝐢𝐯𝐞 𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠

One of the most cited examples in the aviation sector is GE Aviation’s introduction of 3D-printed aviation titanium alloy fuel nozzles for its LEAP engines. These components, previously assembled from 20 separate parts, are now produced as a single unit using additive manufacturing, reducing assembly time and increasing durability. The innovation not only improved component performance but also slashed production costs significantly.

Similarly, Airbus has partnered with APWorks, a subsidiary of Airbus Group, to develop and produce aviation titanium alloy parts using laser additive manufacturing. The initiative is aimed at establishing decentralized production facilities near assembly lines, thereby reducing dependency on long-haul titanium supply chains. In another example, Norsk Titanium, a Norwegian company, has pioneered a process called Rapid Plasma Deposition to produce aerospace-grade aviation titanium alloy components that meet Boeing’s specifications.

𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬 𝐚𝐧𝐝 𝐂𝐞𝐫𝐭𝐢𝐟𝐢𝐜𝐚𝐭𝐢𝐨𝐧 𝐁𝐚𝐫𝐫𝐢𝐞𝐫𝐬 𝐟𝐨𝐫 𝟑𝐃-𝐏𝐫𝐢𝐧𝐭𝐞𝐝 𝐀𝐯𝐢𝐚𝐭𝐢𝐨𝐧 𝐓𝐢𝐭𝐚𝐧𝐢𝐮𝐦 𝐀𝐥𝐥𝐨𝐲

Despite its potential, the adoption of additive manufacturing in aviation titanium alloy production faces several hurdles, particularly concerning regulatory certification. Aviation components must meet stringent standards enforced by regulatory bodies such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA). The variability in microstructure and mechanical properties of printed parts, depending on powder quality and printing parameters, poses significant quality assurance challenges.

Furthermore, the cost of titanium powder suitable for aerospace applications remains high, although decreasing over time due to growing demand and better production methods. Maintaining powder purity and consistency is crucial for ensuring the reliability of printed components, and any deviation can lead to part rejection or failure under stress.

𝐆𝐞𝐧𝐞𝐫𝐚𝐥 & 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/general-and-advanced-materials

𝐅𝐮𝐭𝐮𝐫𝐞 𝐎𝐮𝐭𝐥𝐨𝐨𝐤: 𝐓𝐨𝐰𝐚𝐫𝐝 𝐃𝐞𝐜𝐞𝐧𝐭𝐫𝐚𝐥𝐢𝐳𝐞𝐝 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐌𝐨𝐝𝐞𝐥𝐬 𝐟𝐨𝐫 𝐀𝐯𝐢𝐚𝐭𝐢𝐨𝐧 𝐓𝐢𝐭𝐚𝐧𝐢𝐮𝐦 𝐀𝐥𝐥𝐨𝐲

As additive manufacturing technologies mature and regulatory frameworks become more accommodating, the aviation titanium alloy supply chain in aerospace is poised for a decentralized transformation. Rather than relying on a few global suppliers for forged billets and semi-finished titanium parts, OEMs can increasingly produce customized components on-site or through distributed networks of certified 3D printing facilities.

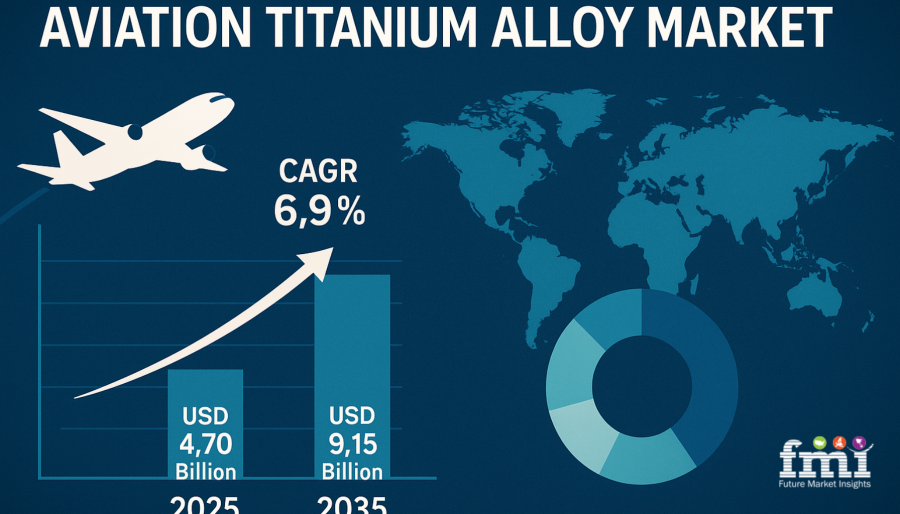

The aviation titanium alloy industry is poised to surge at a steady CAGR of 6.9% between the forecast period between 2025 and 2035. The market is anticipated to hold a market share of USD 4.70 billion in 2025 and is likely to reach a value of USD 9.15 billion.

This paradigm shift has implications for cost, lead time, and sustainability. Decentralized printing reduces transportation emissions, minimizes inventory holding costs, and enhances the ability to respond quickly to design changes or maintenance needs. It also enables smaller aerospace firms to participate in the supply chain by producing certified components without investing in large-scale forging or machining infrastructure.

𝐊𝐞𝐲 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐚𝐭𝐢𝐨𝐧

By Type:

Commercially pure titanium and titanium alloys

By Application:

Structural Airframes, Engines, civilian aerospace, and others

By Microstructure:

Alpha & Near-Alpha Titanium Alloy, Alpha +Beta Titanium Alloy, Beta & Near-Beta Titanium Alloy, and Beta & Near-Beta Titanium Alloy

By Region:

North America, Latin America, Europe, Japan, Asia Pacific Excluding Japan, and the Middle East and Africa.

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Toluene Diisocyanate Market Share Analysis: https://www.futuremarketinsights.com/reports/toluene-diisocyanate-market-share-analysis

Luminescent Materials Market Share Analysis: https://www.futuremarketinsights.com/reports/luminescent-materials-market-share-analysis

Liquid Fertilizer Market Share Analysis: https://www.futuremarketinsights.com/reports/liquid-fertilizer-market-share-analysis

ASEAN Refinery Catalyst Market: https://www.futuremarketinsights.com/reports/asean-refinery-catalyst-market

Chlorotoluene Market Share Analysis: https://www.futuremarketinsights.com/reports/chlorotoluene-market-share-analysis

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release